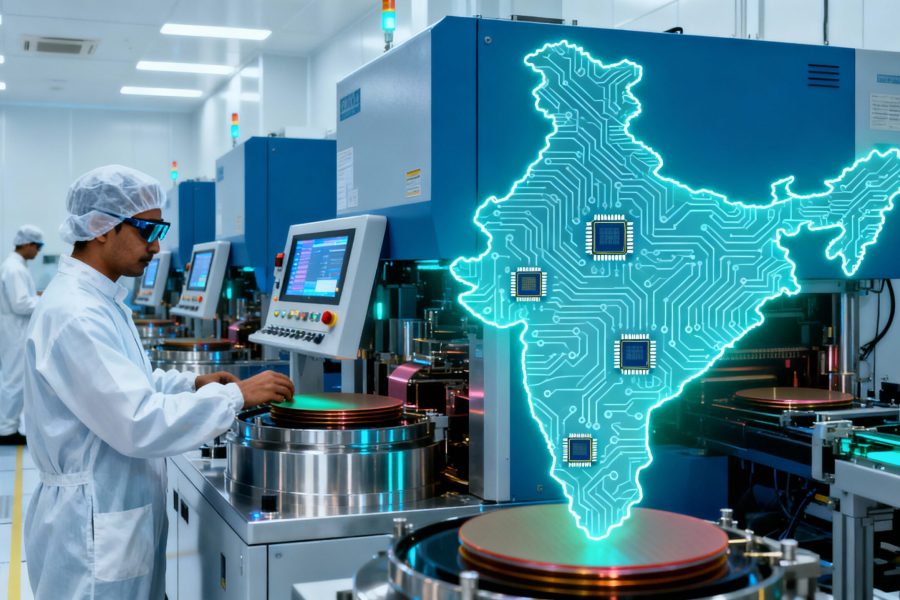

For decades, India has been known as the world’s software powerhouse. Its tech talent fuels Silicon Valley, and most global IT giants operate large development centers here. But today, India is not just writing code — it is building silicon.

With growing government support, billion-dollar investments, and rising global demand for secure chip supply chains, India is stepping into a new era: becoming a global semiconductor manufacturing hub.

1. Why Semiconductor Manufacturing Matters

From smartphones to cars, satellites to smart TVs — chips power almost everything around us.

Countries that control chip manufacturing hold enormous technological and economic advantage.

Yet, global chip production has been heavily concentrated in a few regions like Taiwan, China, South Korea, and the US.

Events like geopolitical tension and pandemic disruptions exposed the risk of over-dependence on limited sources.

This opened a golden window for India.

2. Government Push: Turning Vision into Reality

The turning point came in 2021 with the announcement of the India Semiconductor Mission (ISM) and a ₹76,000 crore incentive package.

The mission focuses on:

✔ Setting up semiconductor fabs (fabrication plants)

✔ Encouraging chip packaging and testing industries

✔ Building talent and R&D ecosystems

Policies like Make in India, Digital India, and PLI schemes further attracted global attention.

The government is actively partnering with global tech giants, approving proposals for fab units in Gujarat, Uttar Pradesh, Telangana, and Karnataka.

3. Mega Investments That Are Rewriting the Industry Map

India is witnessing never-before semiconductor investments:

- Micron’s chip packaging facility in Gujarat

- Tata Group entering semiconductor manufacturing and fab assembly

- Foxconn expressing interest in chip fabrication

- ISMC and Vedanta Semiconductor initiatives

These big moves not only create infrastructure but build industry confidence — a major catalyst for global players.

4. India’s Biggest Strength: Talent and Engineering Capability

India produces millions of engineers each year.

It has decades of experience in VLSI design, embedded systems, and software development.

Many semiconductor innovations in Intel, Qualcomm, Texas Instruments, Nvidia, and AMD have Indian engineers behind them.

This talent advantage gives India a competitive edge — it already has the brainpower for chip design; now it is developing manufacturing muscle.

5. Strategic Geopolitics and Supply Chain Realignment

Global chip demand is soaring due to 5G, AI, electric vehicles, aerospace, and IoT growth.

Countries want trusted diversification away from politically vulnerable regions.

India positions itself as:

- A stable democracy

- A rapidly expanding digital economy

- A growing manufacturing base

This makes India attractive for global reshoring and friend-shoring strategies.

6. Opportunities Driving India’s Semiconductor Story

The next decade will unlock new growth:

✔ Electronics Market Boom

India is one of the fastest-growing electronics consumption markets — smartphones, EVs, appliances, smart cities.

✔ 5G, AI, and Cloud Revolution

Next-gen digital infrastructure demands high-performance chips.

✔ EV and Automotive Growth

Vehicles now require 5X more chips than before — India is becoming a major EV manufacturing hub.

✔ Startup Energy

Deep-tech startups in chip design, AI processors, sensor systems, and semiconductor IP are emerging strongly.

These opportunities create organic demand — ensuring fabs are not just set up, but sustained.

7. Hurdles on the Road — And How India is Tackling Them

Chip fabrication is highly complex.

Challenges include:

- High capital cost

- Power and water requirements

- Supply chain maturity

- Advanced skills in fabrication processes

India’s answer:

✔ Government subsidies and shared risk investment

✔ Partnership with global fabs

✔ Skill development programs and semiconductor courses

✔ Focus on OSAT (Outsourced Semiconductor Assembly & Testing) as an entry stage

This phased approach strengthens capability gradually instead of overnight jumps.

8. The Future: India in the Global Semiconductor Race

India is not competing to replace Taiwan or Korea overnight.

It is building a complementary and strategic position.

Over the next decade, India is expected to:

- Produce advanced packaging solutions

- Manufacture specialty and automotive-grade chips

- Become a major semiconductor design and validation center

- Transform into a trusted global alternative

With strong political will, ecosystem building, and private sector entry, India’s semiconductor future looks bright.

Conclusion

India’s emergence as a global chip manufacturing hub is no longer a distant dream — it is a visible transformation.

A combination of

policy drive, talent strength, industry investment, geopolitics, and market demand

is rewriting India’s technology narrative.

The world is watching India not just as a software nation but as a silicon powerhouse in the making.

For students, tech professionals, investors, and innovators — this is the beginning of a historic opportunity.